The purpose of this guide is to provide a comprehensive overview of how to effectively and safely use a Dewalt drill in 2023. Whether you are a seasoned professional or a DIY enthusiast, this guide will provide you with essential information to help you get the most out of your Dewalt drill. It will cover everything from the history of Dewalt drills to the importance of using them, as well as practical tips for using them effectively.

History of Dewalt Drills

Dewalt has been a leading manufacturer of power tools for over 90 years. The company was founded in 1924 by Raymond E. DeWalt and originally produced woodworking machines. In the 1940s, Dewalt began manufacturing power tools, including the first radial arm saw, which quickly became a staple in woodworking shops. In the 1960s, the company expanded into the professional construction market with the introduction of its first line of portable electric tools. Since then, Dewalt has continued to innovate and produce high-quality power tools, including its popular line of drills.

Importance of Using Dewalt Drills

Dewalt drills are known for their durability, power, and versatility, making them an essential tool for a wide range of applications. Whether you are drilling through wood, metal, or concrete, a Dewalt drill can help you get the job done quickly and efficiently. They are also designed with safety in mind, with features like ergonomic grips and safety clutches to prevent injuries.

Dewalt Drill Components

Before using a Dewalt drill, it is important to understand its components. A typical Dewalt drill consists of a motor, chuck, trigger, clutch, and battery. The motor is responsible for providing the power necessary to turn the chuck, which is the component that holds the drill bit. The trigger is used to control the speed of the drill, while the clutch allows the user to control the torque applied to the bit. The battery provides the necessary power to operate the drill.

Types of Dewalt Drills And Their Features

Dewalt offers a wide range of drill types, each with its own unique features and benefits. Here is a table of some of the most common Dewalt drill types and their features:

| Type of Dewalt Drill | Features |

|---|---|

| Cordless Drill/Driver | Cordless, variable speed control, brushless motor, multiple clutch settings |

| Hammer Drill | Corded or cordless, hammer mode for drilling through concrete and masonry, high torque motor |

| Right Angle Drill | Compact design for tight spaces, angled chuck for drilling at a 90-degree angle |

| Drill Press | Stationary drill for precision drilling, adjustable speed, tilting worktable |

| Impact Driver | Cordless, high-torque output for driving screws and bolts, multiple speed and torque settings |

Dewalt Drill Power And Speed

Dewalt drills are available in a range of power and speed options, each designed for specific applications. Understanding drill power and speed is important for selecting the right tool for the job. Here are some key points to keep in mind:

- Power is measured in volts for cordless drills and amps for corded drills. Higher power typically means greater torque and faster drilling speeds.

- Speed is measured in revolutions per minute (RPM). Variable speed control allows for greater precision and control in drilling. Slower speeds are ideal for drilling through harder materials like metal or concrete, while faster speeds are better for softer materials like wood.

- Brushless motors are becoming increasingly popular in Dewalt drills, as they are more efficient and provide longer battery life than traditional brushed motors.

- When selecting a drill, consider the type of material you will be drilling and the size of the drill bit you will be using. This will help determine the necessary power and speed for the job.

How to Use a Dewalt Drill: Step-by-Step Guide

Using a Dewalt drill may seem straightforward, but it is important to follow certain steps to ensure safety and effectiveness. Here is a step-by-step guide on how to use a Dewalt drill:

Step 1: Read the User Manual

Before using a Dewalt drill, it is important to read the user manual to understand its features, safety precautions, and maintenance instructions.

Step 2: Insert the Battery

Insert the battery into the designated slot and ensure it is securely in place. For corded drills, plug in the power cord.

Step 3: Insert the Drill Bit

Insert the appropriate drill bit into the chuck and ensure it is tightened securely. Use a keyless chuck or key to tighten the chuck, depending on the type of drill.

Step 4: Adjust the Speed and Clutch Settings

Use the trigger to adjust the speed of the drill to match the material you are drilling. Adjust the clutch setting to control the torque applied to the bit and prevent overdriving screws or damaging the material.

Step 5: Position the Drill

Position the drill at the desired angle and use both hands to hold the drill securely. Apply steady pressure and avoid excessive force that may cause the bit to bind or break.

Step 6: Start Drilling

Start the drill by squeezing the trigger and apply steady pressure as you drill through the material. Keep the drill perpendicular to the material to avoid the bit from wandering off course.

Step 7: Finish and Turn off the Drill

Release the trigger once you have completed the drilling and allow the bit to come to a complete stop before removing it from the material. Turn off the drill and remove the battery or unplug the power cord.

Step 8: Clean and Store the Drill

Clean the drill and drill bits, and store them in a dry and secure place. Follow the manufacturer’s recommendations for maintenance and cleaning to ensure the longevity of the drill.

Following these steps will help ensure that you can use your Dewalt drill safely and effectively for a range of applications.

Safety Tips When Using A Drill

Using a drill can be dangerous if proper safety precautions are not taken. Here are some safety tips to keep in mind when using a drill:

- Always wear eye protection, such as safety goggles or a face shield, to protect your eyes from flying debris.

- Wear appropriate clothing, such as long sleeves and pants, to protect your skin from sharp drill bits or flying debris.

- Avoid wearing loose clothing or jewelry that may get caught in the drill.

- Use the drill in a well-ventilated area to avoid inhaling dust or fumes.

- Keep your work area clean and free of clutter to avoid tripping or falling while operating the drill.

- Use a clamp or vise to secure the material you are drilling, if possible, to prevent it from spinning or moving while you work.

- Make sure the drill bit is properly secured in the chuck and tightened before operating the drill.

- Use the appropriate drill bit for the material you are drilling to avoid damaging the bit or the material.

- Use the appropriate drill speed and torque setting for the job to prevent the bit from binding or breaking.

- Always turn off the drill and remove the battery or unplug the power cord before changing the drill bit or making any adjustments to the drill.

- Never touch the drill bit or chuck immediately after use, as they can be hot and cause burns.

Following these safety tips will help ensure that you can use your Dewalt drill safely and effectively, minimizing the risk of injury or damage to the tool.

Maintaining Your Dewalt Drill

Proper Dewalt Drill Storage

Proper storage is essential for maintaining the longevity of your Dewalt drill. Here are some tips for proper Dewalt drill storage:

- Store the drill in a dry and secure place to avoid rust and damage.

- Keep the drill in a case or tool bag to protect it from dust and debris.

- Store the drill with the battery removed to prevent damage from moisture or corrosion.

- Avoid storing the drill in extreme temperatures or direct sunlight.

- Store drill bits separately in a secure location to avoid damage or loss.

How To Clean And Maintain Your Dewalt Drill

Proper maintenance and cleaning can help prolong the life of your Dewalt drill. Here are some tips on how to clean and maintain your Dewalt drill:

- Wipe down the drill with a clean, dry cloth after each use to remove dust and debris.

- Use a soft brush to clean the chuck and drill bit to remove any residue or debris.

- Lubricate the chuck regularly to prevent rust and ensure smooth operation.

- Clean the air vents on the drill to prevent dust buildup and ensure proper ventilation.

- Check the battery contacts and clean them with a dry cloth to ensure a secure connection.

- Follow the manufacturer’s recommendations for cleaning and maintenance.

Common Dewalt Drill Problems And How To Fix Them

Even the most reliable power tools can experience issues from time to time. Here are some common Dewalt drill problems and how to fix them:

- Chuck won’t tighten: Check to make sure the drill bit is the correct size for the chuck and that it is properly inserted. If the chuck is still loose, replace it.

- Overheating: If the drill is overheating, let it cool down before using it again. Check the air vents and clean them to ensure proper ventilation. Avoid using the drill for extended periods of time.

- Low power or battery life: Check the battery contacts and make sure they are clean and securely connected. Replace the battery if it is old or worn out.

- Excessive vibration: Check to make sure the drill bit is properly secured and tighten it if necessary. If the vibration persists, the drill may need to be serviced or repaired.

- Noisy operation: Check the drill’s gear assembly and lubricate it if necessary. If the noise persists, the drill may need to be serviced or repaired.

If you experience any issues with your Dewalt drill, refer to the user manual or contact a professional for assistance.

Tips and Tricks When Using a Dewalt Drill

Tips And Tricks For Efficient Drilling

- Use a center punch to mark the spot you want to drill

- Apply steady pressure when drilling

- Use the correct drill bit for the material you’re drilling

- Start drilling at a low speed and gradually increase as needed

- Use lubricant when drilling through metal to reduce heat and friction

How To Get The Most Out of Your Dewalt Drill

- Charge your battery fully before use

- Use the appropriate drill bit and speed for the job

- Practice good posture and grip when drilling

- Store your drill in a cool, dry place to prolong its lifespan

- Regularly clean and maintain your drill to ensure it operates efficiently

Best Practices For Drilling With A Dewalt Drill

- Use a clamp to hold your workpiece securely

- Wear eye protection and gloves to protect yourself

- Plan your drilling pattern to avoid mistakes and ensure accuracy

- Use a depth stop to control how deep you drill

- Take breaks to avoid overheating your drill or causing injury

Final Words

Using a Dewalt drill can make your DIY or professional projects more efficient and effective. Understanding the components, types, and power and speed settings of the drill is essential for selecting the right tool for the job. Following proper safety precautions, such as wearing eye protection and securing the material, can help prevent injuries and damage to the drill. Proper storage, cleaning, and maintenance can also help prolong the life of the drill. If you experience any issues with your Dewalt drill, refer to the user manual or contact a professional for assistance. With the proper knowledge and care, your Dewalt drill can be a reliable and versatile tool for all your drilling needs.

FAQs

How to troubleshoot a Dewalt drill that won’t turn on?

If your Dewalt drill won’t turn on, try the following steps:

- Check the battery or power source to ensure it is properly connected and charged.

- Check the trigger to ensure it is not jammed or stuck.

- Check the fuse or circuit breaker to ensure it has not tripped.

- Check the switch or brush assembly for signs of damage or wear and replace if necessary.

How to select the right Dewalt drill bit for a specific project?

Selecting the right Dewalt drill bit for a specific project depends on the material you will be drilling into. Consult the manufacturer’s recommendations or a drilling chart to determine the appropriate bit type and size for the job.

Can a Dewalt drill be used to mix cement or mortar?

No, Dewalt drills are not recommended for mixing cement or mortar as this can cause excessive wear and tear on the tool and can result in damage or injury.

What is the recommended maintenance routine for a Dewalt drill?

The recommended maintenance routine for a Dewalt drill includes regular cleaning, lubrication of the chuck, checking and cleaning the air vents, and following the manufacturer’s recommended maintenance schedule. Refer to the user manual for specific recommendations.

How to handle a Dewalt drill battery that won’t hold a charge?

If your Dewalt drill battery won’t hold a charge, it may be time to replace it. Check the battery contacts for signs of damage or wear, and make sure they are clean and securely connected.

What safety precautions should I take when using a Dewalt drill?

Some safety precautions to take when using a Dewalt drill include wearing eye protection, securing the material being drilled, avoiding loose clothing or jewelry, using the appropriate speed and torque settings, and turning off the drill before making any adjustments.

Can I use a Dewalt drill for screwing?

Yes, a Dewalt drill can be used for screwing. Use the appropriate screwdriver bit and adjust the clutch setting to avoid overdriving or damaging the screw.

How to choose the right voltage for a Dewalt drill?

The voltage of a Dewalt drill depends on the type of project you will be working on. Higher voltage drills are ideal for heavy-duty applications, while lower voltage drills are suitable for lighter projects.

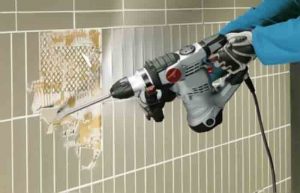

Can I use my Dewalt drill to create a hole in a tile?

Yes, a Dewalt drill can be used to create a hole in a tile. Use a diamond-tipped drill bit and work slowly and carefully to avoid cracking or damaging the tile.