Are you looking to take on a DIY project that requires drilling through tough surfaces like concrete or masonry? A rotary hammer drill may be the perfect tool for the job. This guide will provide you with all the information you need to know about using a rotary hammer drill, including safety precautions, preparation, techniques, common applications, troubleshooting, and maintenance.

What is a Rotary Hammer Drill

A rotary hammer drill is a powerful tool designed to drill holes in tough surfaces like concrete, masonry, and stone. It uses a combination of rotary motion and hammering action to break through these materials. Unlike regular drills, rotary hammer drills have a special mechanism that allows them to deliver more force, making them ideal for heavy-duty drilling tasks.

There are three main types of rotary hammer drills: corded, cordless, and SDS-max. Corded drills require a power outlet and are generally more powerful than cordless drills. Cordless drills are battery-powered and more portable but may not have as much power as corded drills. SDS-max drills are the most powerful type of rotary hammer drill and are typically used for commercial or industrial applications.

Safety Precautions

Before using a rotary hammer drill, it’s important to take the necessary safety precautions. Here are some tips to keep in mind:

Wear Safety Gear

Always wear the appropriate safety gear when using a rotary hammer drill. This includes safety glasses, a dust mask, ear protection, and gloves.

Check the Drill

Before using the drill, make sure it’s in good condition. Check the cord or battery for damage, ensure the chuck is tight and secure, and look for any signs of wear or damage.

Use the Right Drill Bit

Make sure you use the correct drill bit for the material you’re drilling through. Using the wrong drill bit can cause damage to the drill and may even be dangerous.

Keep the Work Area Clear

Clear the work area of any obstructions, and ensure there’s enough space to move around. Make sure the area is well-lit so you can see what you’re doing.

Use Two Hands

Always use both hands to operate the drill. This will give you more control and help prevent accidents.

Be Aware of Electrical Hazards

When using a corded rotary hammer drill, be aware of electrical hazards. Keep the drill away from water, and make sure the power cord is not damaged or frayed. If you’re working in a damp or wet area, use a cordless drill instead.

Use the Hammer Stop Function

Some rotary hammer drills have a hammer stop function that allows you to turn off the hammering action and use the drill as a regular drill. This can be useful for drilling through materials that don’t require the hammering action. If your drill has this feature, use it when appropriate to reduce the risk of injury or damage to the material you’re drilling.

Remember, safety should always be your top priority when using a rotary hammer drill. By taking the necessary precautions and using the correct technique, you can avoid accidents and injuries and complete your drilling tasks with ease.

Preparing for Use

Once you’ve taken the necessary safety precautions, it’s time to prepare the drill for use. Here’s what you need to do:

Select the Right Drill Bit

Choose a drill bit that is appropriate for the material you’ll be drilling through. Look for a bit that is the right size and shape, and make sure it’s compatible with your rotary hammer drill. Carbide-tipped drill bits are the most durable and suitable for drilling through tough materials like concrete and masonry.

Install the Drill Bit

Insert the drill bit into the chuck and tighten it securely. Make sure the bit is straight and centered in the chuck to prevent wobbling and damage to the drill. Use a chuck key or the drill’s built-in chuck mechanism to tighten the chuck properly.

Adjust the Depth Gauge

If you need to drill to a specific depth, adjust the depth gauge on the drill to ensure you don’t drill too deep. The depth gauge is usually located on the side of the drill and can be adjusted by turning a knob or sliding a lever. Make sure to read the manufacturer’s instructions for your specific drill to properly adjust the depth gauge.

Secure the Workpiece

To prevent the workpiece from moving while you’re drilling, secure it with clamps or a vice. This will help you maintain accuracy and prevent accidents. Make sure the workpiece is stable and won’t move or shift during drilling.

Using the Rotary Hammer Drill

Using a rotary hammer drill is a bit different from using a regular drill. Here are some tips to help you use your rotary hammer drill effectively:

Start Slowly

When you first start drilling, begin at a low speed to get a feel for the drill. Once you’re comfortable with the speed and motion, you can increase the speed as needed.

Apply Pressure

Apply steady pressure to the drill as you’re drilling. This will help you maintain control and prevent the bit from getting stuck. Don’t force the drill; let it work at its own pace and apply gentle pressure.

Use the Correct Technique

The correct technique will depend on the material you’re drilling through. For example, when drilling through concrete, use a hammering motion to break up the material. When drilling through metal or wood, use a rotary motion.

Maintain Control

Maintain control of the drill at all times. Keep both hands on the drill and don’t let the bit wander or get stuck. If the drill starts to get away from you, release the trigger immediately and regain control.

Use Cooling Lubricant

When drilling through tough materials like concrete or masonry, use a cooling lubricant like water to keep the bit cool and prevent overheating. Apply the lubricant periodically as you’re drilling.

Take Breaks

Rotary hammer drills can be heavy and tiring to use for long periods of time. Take breaks as needed to prevent fatigue and ensure that you’re able to maintain control of the drill.

By following these tips and using the correct technique, you’ll be able to use your rotary hammer drill effectively and complete your drilling tasks with ease. Remember to always wear the appropriate safety gear and take the necessary precautions to prevent accidents and injuries.

Common Applications

Rotary hammer drills are versatile tools that can be used for a variety of applications. Here are some common uses:

Drilling through Concrete

Rotary hammer drills are ideal for drilling through concrete. Use a hammering motion to break up the material, and make sure you use a carbide-tipped drill bit designed for concrete. Concrete is a dense material and requires a lot of force to drill through, so a rotary hammer drill is the best tool for the job.

Drilling through Masonry

Masonry includes materials like brick, block, and stone. When drilling through masonry, use a hammering motion and a masonry bit designed for the specific material you’re drilling. Masonry bits are similar to concrete bits but may have a different shape or angle to better penetrate the material.

Installing Anchors

If you need to install anchors in concrete or masonry, a rotary hammer drill can make the job easier. Use a masonry bit to drill the hole and then insert the anchor. Anchors are used to secure objects like shelves, cabinets, and fixtures to walls or ceilings.

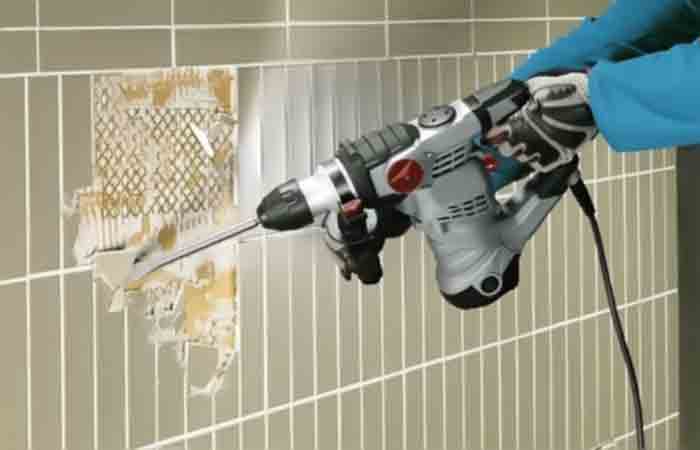

Removing Tile

If you need to remove tile from a concrete or masonry surface, a rotary hammer drill with a chisel bit can help break up the tile quickly and easily. The chisel bit is designed to chip away at the tile and remove it from the surface.

Chiseling

A rotary hammer drill can also be used for chiseling tasks. Use a chisel bit to remove material or create a channel in concrete or masonry. This can be useful for creating decorative features or removing excess material.

Troubleshooting and Maintenance

To keep your rotary hammer drill in good condition and functioning properly, it’s important to perform regular maintenance and troubleshooting. Here are some tips to help you maintain your drill:

Clean the Drill and Chuck After Each Use

After each use, clean the drill and chuck with a soft cloth or brush to remove any debris or dust. This will help prevent the buildup of dirt and dust that can interfere with the drill’s performance.

Check the Carbon Brushes Regularly

The carbon brushes in your rotary hammer drill will wear down over time and will need to be replaced periodically. Check them regularly and replace them if they’re worn down to about 1/4 inch in length.

Lubricate the Chuck and Moving Parts

To keep the chuck and other moving parts working smoothly, lubricate them periodically with a light machine oil. This will help reduce friction and prevent wear and tear on the drill.

Store the Drill in a Dry, Cool Place

When you’re not using your rotary hammer drill, store it in a dry, cool place to prevent rust and other damage. Keep it away from moisture and extreme temperatures, and store it in a protective case or bag.

If you encounter problems while using your rotary hammer drill, here are some common issues and solutions:

- Drill bit gets stuck: Stop drilling and turn off the drill. Release the chuck and remove the bit. Clean the chuck and re-insert the bit.

- Drill won’t turn on: Check the power source and ensure the cord or battery is connected properly. If using a corded drill, check the outlet for power.

- Drill overheats: Let the drill cool down for a few minutes. If the problem persists, check the air vents and clean them if necessary.

By performing regular maintenance and troubleshooting, you’ll be able to keep your rotary hammer drill in top condition and avoid problems while using it. Remember to always follow the manufacturer’s instructions for your specific drill, and take the necessary safety precautions to prevent accidents and injuries.

FAQs

What is the difference between a hammer drill and a rotary hammer drill?

A hammer drill uses a back-and-forth motion to create a hole, while a rotary hammer drill uses a combination of rotary motion and hammering action to drill through tough materials like concrete.

What is the best rotary hammer drill for concrete?

The best rotary hammer drill for concrete will depend on your specific needs and budget. Look for a drill with a high power output, variable speed control, and a good selection of drill bits.

How do I know which drill bit to use for a specific job?

Choose a drill bit that is appropriate for the material you’ll be drilling through. Look for a bit that is the right size and shape, and make sure it’s compatible with your rotary hammer drill.

Can I use a rotary hammer drill for woodworking?

While rotary hammer drills are designed for heavy-duty drilling, they are not recommended for woodworking. Instead, use a regular drill or a drill press for woodworking tasks.

How often do I need to replace the carbon brushes in my rotary hammer drill?

Carbon brushes will wear down over time, so it’s important to check them regularly. Replace them when they’re worn down to about 1/4 inch in length.

Final Words

A rotary hammer drill is a powerful tool that can make drilling through tough materials like concrete and masonry easier and more efficient. By following the safety precautions, preparing the drill properly, using the correct technique, and performing regular maintenance, you can ensure that your rotary hammer drill performs at its best for years to come. Remember to choose the right drill bit for the job, use the correct technique, and wear the appropriate safety gear. With this guide, you’ll be able to use your rotary hammer drill with confidence and tackle even the toughest drilling tasks.